1. Site organization

Preparing and organizing the site are crucial to minimizing the risk of accidents and optimizing operational efficiency. It is recommended to clearly mark storage areas and ensure access routes are stabilized with a minimum width of 3 meters to facilitate the movement of handling equipment.

Key points:

- Storage areas should be kept away from electrical infrastructure.

- Access routes must be stabilized.

- Specific precautions should be taken for the movement of cranes and other lifting equipment.

2. Handling products

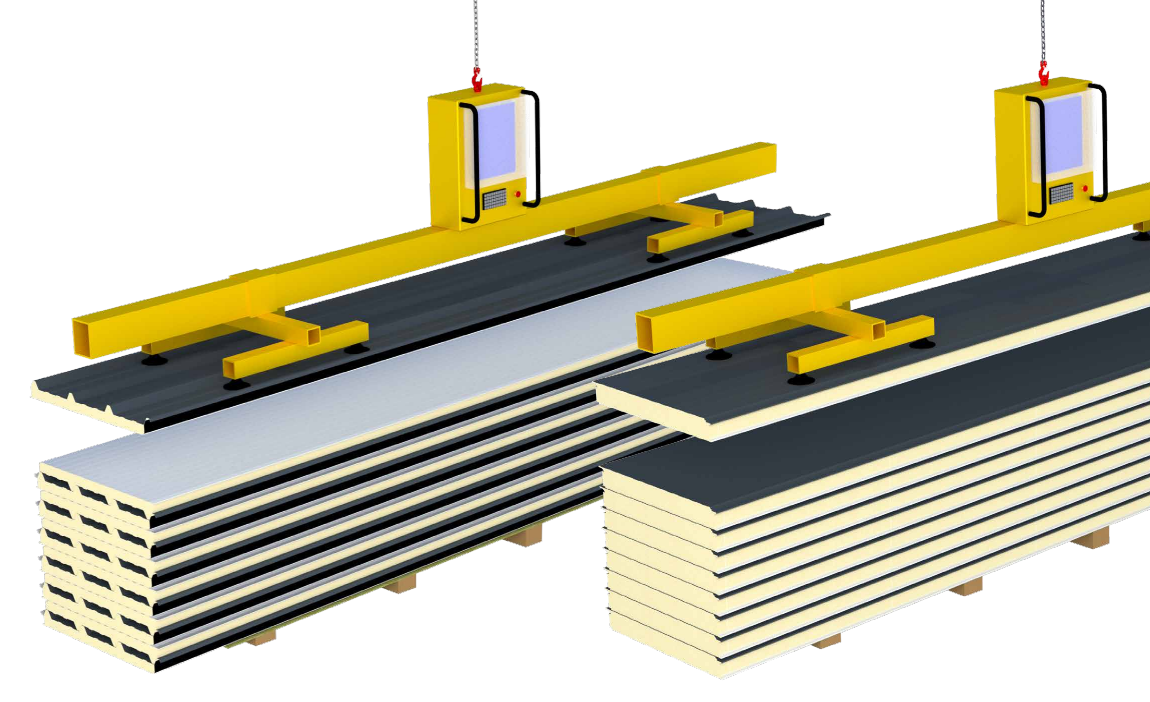

Handling sandwich panels and roofing profiles must be done with appropriate equipment to prevent deformation or damage. Joris Ide recommends using vacuum lifters for sandwich panels and adjustable forks for forklifts, especially for long packages.

Key points:

- The lifting beam must be centred in relation to the panel’s centre of gravity with a minimum grip of 0,15 kg/cm² of the suction cup.

- For panels shorter than 10 m, the distance between the attachments is 3 to 5 m.

- For lengths exceeding 10 m, the maximum distance between the attachments is 6 m.

- The protective film must at least be removed where the suction cup will be placed.

- The handling of mineral wool sand[wich panels (Vulcasteel range) must be done on the edge, without resting on the interlocking edges.

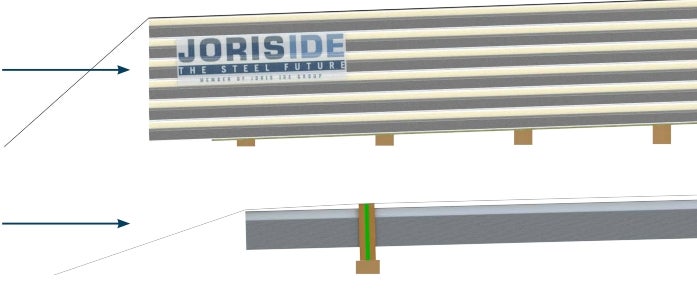

3. Storing products

Products must be stored under optimal conditions to avoid issues like corrosion and condensation. Packages should be tilted at a 5 to 10% angle to allow water drainage. Products should be placed on a stable, ventilated surface, protected from moisture and direct sunlight.

Key points:

- Tilt packages for proper water drainage.

- Store on a stable, dry surface.

4. Packaging and protection

Product packaging plays a crucial role in protecting materials during transport and storage. Profiles and panels are often wrapped in thick films and secured with wooden supports to allow safe stacking. Protective films should be removed within a month of delivery, especially if exposed to sunlight.

Key points:

- Packaging includes peelable protective films.

- Remove the film within one month of delivery.

- Specific storage conditions for products sensitive to climate variations.

5. Transport and unloading

Transporting products requires special precautions to preserve their integrity. During unloading, it is essential to protect the products from the sharp edges of steel sheets and maintain proper spacing between the forks and packages to avoid any damage.

Key points:

- Handle profiles and panels with care during unloading.

- Use wooden planks to protect slings.

- Follow specific recommendations for unloading with cranes and forklifts.